Design of complex parts

Manufacturing complex parts requires a high level of expertise in mould making. The Quéplast team has experience in injection moulding.

Since 1997, we've been designing complex parts :

- Handle complex geometry

- Reconcile design requirements with those of plastic injection and production processes

- Develop and optimize your injection parts from a sketch or 3D plan

We support you from the very beginning—when your parts are initially developed—in order to adapt them to the injection-moulding process.

Quéplast helps to optimize your parts and meet your unique specifications. We work with you from the outset of a project to identify:

- Undercut

- The balance between your wall thickness

- Optimum angles

- Possible sink marks

- Potential distortion

- Weld lines

- Surface finishes

- Tolerances

- The rays

- Etc.

- Develop parts that meet your criteria and specifications

- Design stable and efficient moulds for the duration of their useful life

- Find the best compromise to produce tools at a competitive cost

Plastic injection moulding

With our expertise in injection moulding, we can manufacture parts with any type of masses. Through custom moulding, they meet your requirements.

What’s more: the diversity of our equipment enables us to produce small and large series of parts.

How does Quéplast meet your needs?

- Qualified team ready to listen

- Fast and local production of quality parts

- Strict, rigorous controls on each product batch

- Next-generation equipment and processes

The integrated quality control in the press and peripheral management system enables preventive control to avoid any production anomalies.

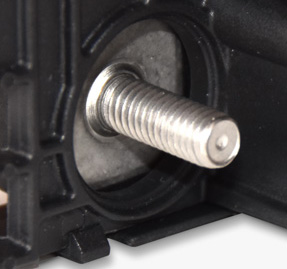

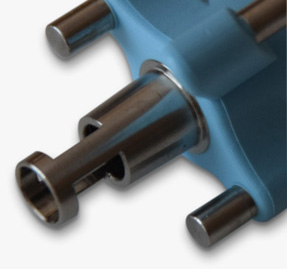

Over-moulding of plastics and inserts for small and large series

Over-moulding consists of moulding on a plastic part, piece of metal, an insert or other materials. Over-moulding can be achieved by a mechanical or chemical bond.

Since 1997, Quéplast has excelled in this specialized niche, optimizing the parts we manufacture to meet strict specifications and features.

What are the advantages of over-moulding?

- Protect inserts or get better torque

- Take advantage of the features of 2 different plastics (rigid and soft)

- Meet sealing standards

- Acquire better impact resistance, different colours on the same part, and improved ergonomics

- Satisfy aesthetics criteria

- Etc.

From our experience over time, we have optimized our over-moulding process. We have also developed working methods that enable us to provide high-performance products at competitive prices.

To meet your different needs in terms of quantity, we have the capacity to produce over-mouldings in small and large series.

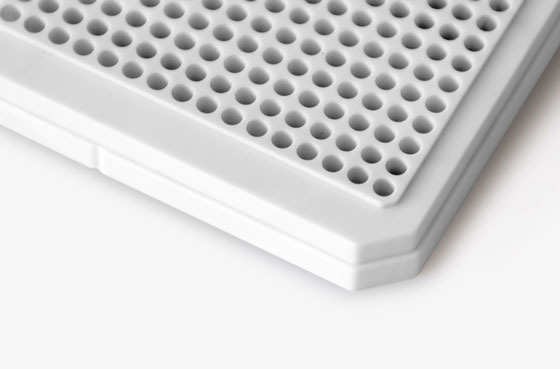

Micro injection of high-precision parts

Our injection-moulding equipment is equipped with high-precision thermoplastic moulding machines. We are able to meet tolerances of ±9 microns in production and with a mass from 0.007 g. We also have a series of cutting-edge robots.

Thanks to our proven track record in micro injection, we specialize in engineering resins, such as:

- PEEK

- PEI

- PSU

- PMMA

- PA 6

- PA 11

- PPSU

- PEK

- Etc.

We have the ability to produce both small and large series of parts.

Specialized in engineering resins

Quéplast has a long-standing expertise in engineering resins, based on your requirements and the desired application. We have a wide range of materials to achieve the specs you need for:

- Lightness

- Electrical properties

- Impact resistance

- High-temperature resistance under loads

- Thermal properties

- Mechanical properties

- Chemical resistance

- Rigidity

- Low humidity absorption

- Low coefficient of friction

- Transparency

- Dimensional stability

- Etc.

We work with many different engineering resins. Here are just a few examples:

ABS, ABS/PA, ABS/PC, ASA, LCP, PC, PS, PC/ABS, PA (6, 66, 12, 11), PE, PEEK, PPSU, PPS, PETP, PS, TPO, PC/PBT, PC/PET, PBTP, PSU, PMMA, PPA, PMP, PE, PPO, PP, PV, POM (ULTEM), PVC, SAN, TPE, TPU.

ISO Class 8 cleanrooms

We have an ISO Class 8 cleanrooms at our disposal within which we manufacture parts or package them in a controlled environment. We also can work in an ISO Class 7 cleanroom.

Rigorous quality assurance

At Quéplast, you can rely on a meticulous team committed to continuous improvement. And this holds true for each of its members in their everyday work.

We check all the parts we design to ensure they meet the required quality and safety standards.

To ensure the quality of our plastic parts, we have established procedures throughout the entire development and manufacturing process. These procedures enable us to control our raw materials, production equipment, inspection plans, mechanical tests, assemblies, measurements, packaging methods, and more.

Tests and controls adapted to your requirement

CPK, SPC, AQL, FAI

Laser measuring equipment with an accuracy of ±2 microns

Customized inspection plan according to your needs

Complete metrology (layout)

High-precision scale, up to 0.0001g

Product identification system to trace manufacturing batches and raw material at any time (5-year traceability)

Well-documented product specifications

PFMEA, AMDEC, DOE, PPAP

en

en  fr

fr